Scot

Athletic Supporter

I see a lot of misinformation propagated here. I like people to be well informed and I'm happy to share 20 years of production engine calibration experience with anyone that wants. Knowledge is power.

1. Bigger injectors will not kill your fuel economy - IF YOU ADJUST YOUR CALIBRATION FOR THEM.

Yes, bigger injectors flow more fuel, but with proper calibration and closed loop fuel control, you will not notice a difference in fuel economy.

Here are the sort of calibrations available to tuners with respect to injector flow:

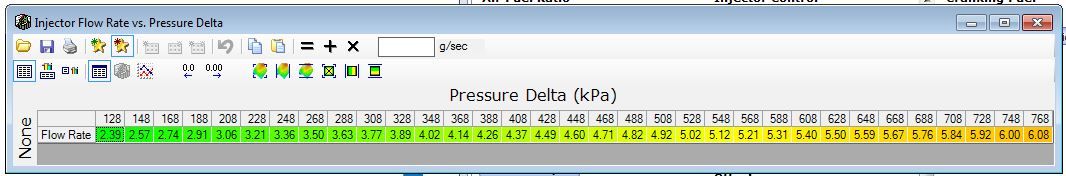

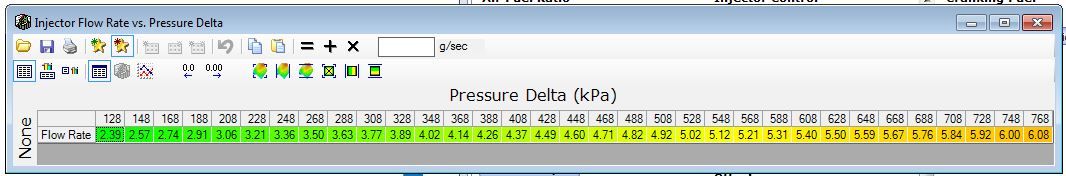

Flow rate vs. pressure:

This is the main table you adjust when you change your injector sizing. Basically, it is how much fuel the injector can flow (in grams per second) at a given fuel pressure. The array's axis is in "delta pressure" - but that's to let us know the pressure is in "gauge", not absolute. So, this array lets us know at a given fuel pressure, we get a certain amount of flow. The ECU can then calculate the required injector pulsewidth for the amount of fuel needed.

Now, if someone doesn't know how to properly calibrate big injectors, they might find a problem of running too rich at idle, and that would negatively affect fuel economy a bit, but it's pretty hard to mess up the basic conversion.

To be continued...

1. Bigger injectors will not kill your fuel economy - IF YOU ADJUST YOUR CALIBRATION FOR THEM.

Yes, bigger injectors flow more fuel, but with proper calibration and closed loop fuel control, you will not notice a difference in fuel economy.

Here are the sort of calibrations available to tuners with respect to injector flow:

- Flow rate vs. Pressure - I'll get to that later

- Flow rate mult vs. volts - this compenstes the injector pulsewith based on system voltage

- Flow rate mult vs MAP - this compenstes the fuel injected based on intake manifold pressure. It is harder to push fuel into a manifold with 20 psi boost than with 10 psi vacuum.

- Flow rate mult vs IAT - this compensates fuel flow vs intake air temperature. In a port-fuel injected engine, there is an ever-changing "puddle" of liquid fuel. The size of this puddle - and what ends up getting in the cylinder - changes with temperature

- Flow rate mult vs Flow - Injector flow rates are non-linear as they approach the min flow regions.

Flow rate vs. pressure:

This is the main table you adjust when you change your injector sizing. Basically, it is how much fuel the injector can flow (in grams per second) at a given fuel pressure. The array's axis is in "delta pressure" - but that's to let us know the pressure is in "gauge", not absolute. So, this array lets us know at a given fuel pressure, we get a certain amount of flow. The ECU can then calculate the required injector pulsewidth for the amount of fuel needed.

Now, if someone doesn't know how to properly calibrate big injectors, they might find a problem of running too rich at idle, and that would negatively affect fuel economy a bit, but it's pretty hard to mess up the basic conversion.

To be continued...